After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

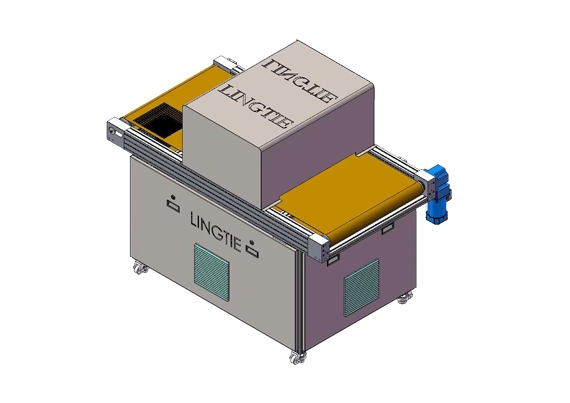

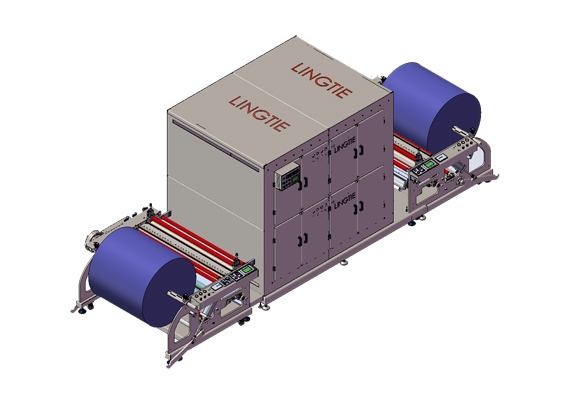

Pre-shrink UV Curing Machine

Brand:

LingtieItem NO.:

LTB-600Payment:

T/T, T/CMarket Price:

$18000Shipping Port:

Xiamen ,ChinaLead Time:

10 days after advance payment

Product Name: Pre-shrink Curing Oven Series

The Parameter for one of Part---IR Hot Dryer

- Inner loops: 60 meters

- Temperature range: 37-140 Celsius (customized Temperature would reach to 200 )

- Insulation Layer Thickness: 50 mm

- Power Supply: 220 V, 22KW

- Machine Size : 2830 * 1060 * 2150 mm

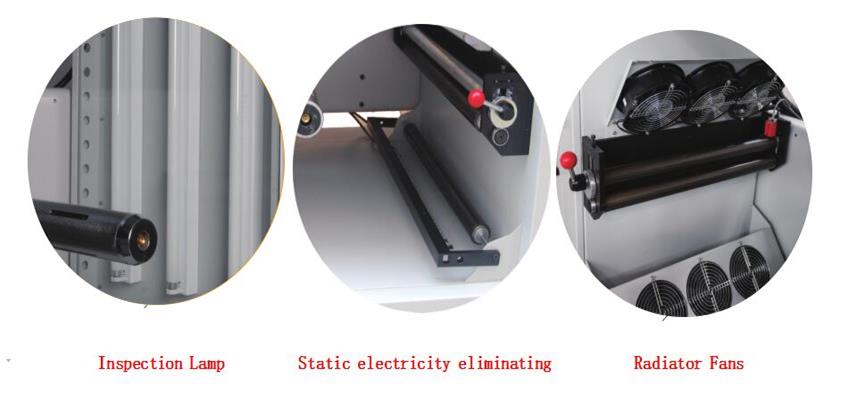

What kinds of main parts in the curing dryer oven?

- Suction Motor: 6 sets

- Frequency converter: 1 set

- Temperature Controller: 4 sets ( 4 sides heating and control temperature independently )

- Cooling Fan: 6 fans

How many Option functions the pre-shrink hot air dryer machine have?

- Equipped with Laminating Device

- Powered UV dryer Device

- 200 Celsius tunnel oven

- Four sides heating and thermostats controller

- Static electricity eliminating device

- Web guiding device/correction device

The details for the Option Functions

Features of the Pre-shrink Curing Oven Machine

- Independent four digital display thermostats control the temperature of 4 sides respectively, making temperature control more convenient and accurate.

- The imported photoelectric switch can sense any printed material and automatically track the speed of the press for running.

- Adopt variable frequency converter, Shilin industrial control, brand motor, brand speed reducer, more accurate control, guarantee stable operation of the machine.

- The exclusive suction tension, ventilation size, heating power (current) can be any stepless adjustment, easy to control the physical tension, to protect the printed material does not stretch and thermal deformation.

- Exclusive installation of the insulation layer, so that a more balanced temperature. Reduce surface temperature, avoid operator burns, save power, save energy, and protect the environment.

Previous:

Hot air dryerNext:

LED UV Dryer

-

Oven/drying box -LTB-350

Oven/drying box -LTB-350

Hot air drying machine is an important part of the screen printing process, It Can be customized according to the actual needs of users of various specifications and functions of the oven (oven/drying box)

-

UV dryer for sheet printing machine

UV dryer for sheet printing machine

UV energy "cures" inks and varnishes in a fraction of a second. A UV system consists essentially of the following components: UV lamps, reflectors, lamp housings, a cooling system and an electronic operating and control system.

-

Industry Automatic Hot Air Dryer

Industry Automatic Hot Air Dryer

The industry automatic hot air dryer is an efficient drying solution used in food, chemical, and pharmaceutical industries. It quickly removes moisture with a hot air circulation system, offering energy-saving, stable performance, and easy operation.

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062