After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

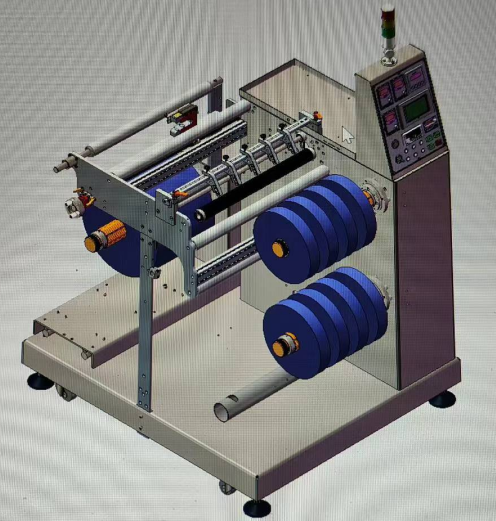

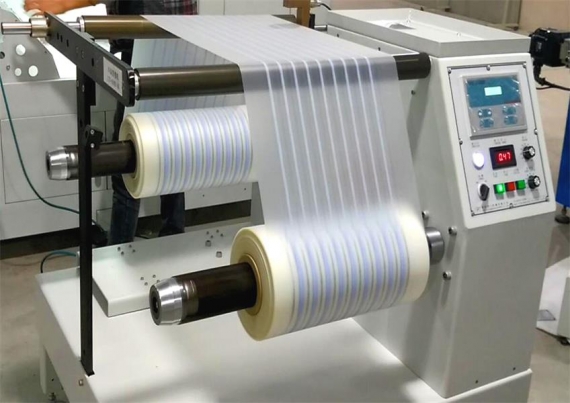

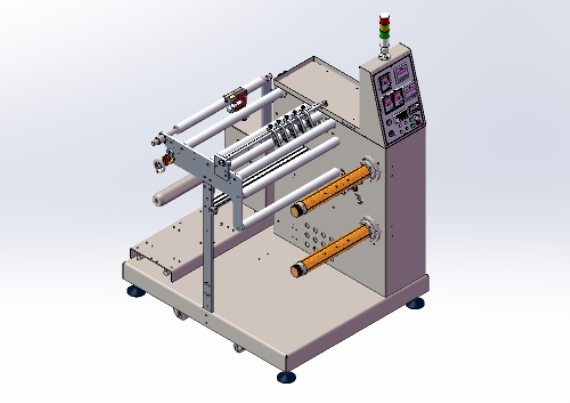

Slitting machine with 2 rewinding shafts

This slitting rewinder is ideal for manufacturers seeking efficiency, precision, and automation in their converting processes

Brand:

LingtieItem NO.:

LTD-600BMarket Price:

$6800Product Origin:

ChinaColor:

silver whiteShipping Port:

Xiamen portLead Time:

15-30 days after advance payment

A slitting machine with 2 rewinding shafts is a versatile piece of equipment designed for precision cutting and rewinding of various materials such as paper, plastic, film, foil, and more. This advanced industrial machine is essential for converting large rolls of material into smaller, more manageable rolls of specific widths.

Equipped with two rewinding shafts, this slitting machine offers enhanced efficiency and productivity .

**Key Features:**

- **Dual-Shaft Rewinding: Equipped with two independent rewinding shafts for uninterrupted operation—two shaft winds the finished roll at the same time, maximizing efficiency.

**Precision Slitting: Utilizes razor blades/ vertical knife, , accurate slitting of materials into narrower widths.

**Automatic Transfer System: Seamless roll changeover with automatic web transfer between shafts, reducing manual intervention and increasing productivity.

**Tension Control: Advanced tension control ensures consistent winding quality and prevents defects like telescoping or wrinkling.

**User-Friendly HMI: Touchscreen interface for easy setup, monitoring, and adjustment of slitting parameters, speed, and tension.

**Robust Construction: Heavy-duty frame and components for durability, supporting high-speed operation and heavy roll weights.

**Versatility: Handles a wide range of materials, thicknesses, and roll diameters, making it suitable for packaging, printing, and converting industries.

**Applications:**

- Plastic films (PP, PET, BOPP)

- Aluminum foils & laminates

- Paper & label stocks

- Non-woven fabrics

**Advantages:**

✔ **Higher Productivity** – Continuous operation with dual-shaft rewinding

✔ **Superior Wound Roll Quality** – Even tension and precise alignment

✔ **Reduced Downtime** – Quick roll changeovers

✔ **Customizable** – Configurable for different slitting methods and material types

| Max.width | 600mm | ||

| Max.bearing load weight | 60kgs | ||

| Power supply | 1-Phase, 220V, 1500W | ||

| Uwind & Rewind air Shaft | 3inch*600mm | ||

| Tension | 1~25N | ||

| Speed | 0-80 m/min | ||

| Weight | 330kgs | ||

| Specification | 1150*1060*1220mm (L*W*H) |

-

Winding Rewinding Machine

Winding Rewinding Machine

A Winding rewinding machine is a machine designed for making the unwinding edge straight, slitting the big roll to small rolls. This machine also used for ink jet printing.

-

Automatic Rewinding Machine

Automatic Rewinding Machine

A rewinding machine is a machine designed for making the unwinding edge straight, slitting the big roll to small rolls.

-

Doctoring Rewinding Machine

Doctoring Rewinding Machine

An Automatic rewinding machine is a machine designed for making the unwinding edge straight, remove dust on the film surface. This machine also used for ink jet printing.

-

Roll Rewinding Machine

Roll Rewinding Machine

This customized Doctoring Rewinding Machine used for the medical gauze rewinding under the consistent tension by a Japanese professional enterprise.

-

Rewinding laminating machine

Rewinding laminating machine

Automatic Rewinding machine with laminating and protect film peel off function .

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062