After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

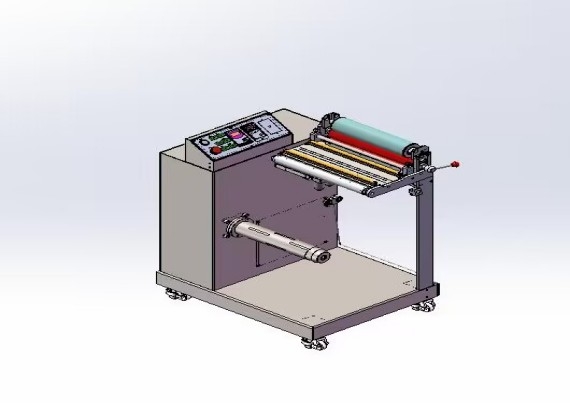

Automatic Feeder Machine

Brand:

LingtieItem NO.:

LTC-900DPayment:

T/T, T/CMarket Price:

$10000Shipping Port:

Xiamen ,ChinaLead Time:

10 days after advance payment

Most of the customized Heavy feeders Machine are available in either standard finish or customized finish for an option. All kind of Feeding Machine in Lingtie are customized Producing model according to your requests; it can use with a printing machine, roll to sheet cutting machine.

The Features for the Heavy Feeding Machine as below:

- Can be installed synchronous double-sided dust, corresponding to the electronics industry, labor-saving, time-saving.

- The body using electrostatic spraying - paint, solvent resistance, cannot afford paint.

- Some user-friendly design, conducive to operation

- Rewinding axis adopts air rising shaft, which only needs to easily inflated and suitable for all kinds of crowds.

The parameter for the Standard Roll Feeder Machine

- Main Motor: 370 w

- the Speed Ratio : 1:5

- Frequency Converter

- Magnetic Power Brake: 25 kg

- Air Shafts : 3 " (76 mm, rewinding shaft )

customized Functions for Automatic Feeder Machine

- Suspension Feeding Machine ( non-scratch material function )

- The Peeling Film & Static Eliminator Feeder Machine

- The Mini Feeding Machine for Printing Machine or Packaging

- The Simplest Feeder Machine for Printing Machine or Packaging

The Mini Feeding Machine & The Simplest Feeding Machine for Sale

The Peeling Film Feeding Machine & The Suspension Feeding Machine in Lingtie Machinery

Previous:

Roll to Roll Label PressNext:

Recoiler

-

Recoiler

Recoiler

This kind of Recoiler Machine could go with many different types of machines such as the roll to roll screen printing machine, packaging machine and curing oven.

-

unwinder

unwinder

Simple unwinder ,which can be work together with all roll to roll screen printing machine .

-

Hot Melt Powder Coating Machine

Hot Melt Powder Coating Machine

the hot melt Powder Coating Machine is scattering the hot melt powder on the roll transfer products, such as cloth labels, transfer paper, transfer film, pyrography, wallpaper, etc.

-

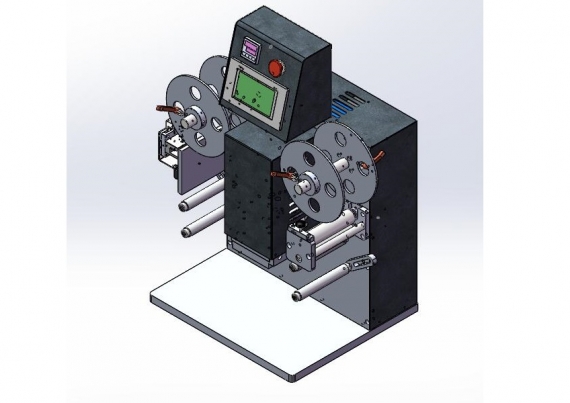

Roll to Roll Label Press

Roll to Roll Label Press

The Roll to Roll Label Press, auxiliary for the roll to roll screen printing machine, Ease to transfer all roll labels.

-

Semi-automatic screen printing machine

Semi-automatic screen printing machine

Quick Details Place of Origin: Fujian, China Applicable Industries: Garment Shops, Building Material Shops, Manufacturing Plant..... After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service Certification: SGS CE ISO-9001 Automatic Grade: Semi-Automatic Brand Name: Lingtie Condition: New Warranty: 1 year Model: LTD-600C Printing area: 400*600mm Plate Type: Screen Printer Voltage: 220v Power supply: 380v/3kw/50HZ Key Selling Points: Long Service Life material Thickness: 0.1-50mm Machine size: L1270*W850*H1630mm Packaging & Delivery Selling Units: Single item Package Type:wooden boxes for sea transportation Lead Time : 15 days after advanced payment. Video Description Product Description Semi-Automatic sheet fed screen printing machine ,is suitable for Flat surface printing on Printed circuit boards, non-woven ,Textile transfers, Paper , Stickers, Membrane switch,Signage, Glass, Wooden board, PVC film and so on 1.Squeegee carriage on Hard Chrome Plated solid steel shaft with linear bearing motion. 2. Adjustable screen frame holder 3. Variable printing stroke length 4. Single/Double stroke selection 5. Parallel screen frame movement(Convenient for spot UV varnish and low viscosity inks to avoid ink spillage all over the screen) 6. Peel off mechanism (To achieve fine reproduction of halftone dots and avoid smudging, bleeding and smearing) 7.Adjustable squeegee angle from 0 to 30º 8.Aluminium extruded squeegee holder & coater for even pressure 9.Bed movement for registration x, y, & Rotary ±10 mm 10.Emergency Rod / Stop for safety of operator 11.Castor wheels for easy mobility 12.Printing operation by foot switch or automatic cycle, with dwell timer 0-10 sec. Model Printing area (mm) ZLA-6090A 600*900 ZLA-70100A 700*1000 ZLA-4060B 400*600 ZLA-450PA 300*450 ZLA-45FA 300*450

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062