After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

PVC panel screen printing machine

Brand:

LingtieItem NO.:

LTA-4050Payment:

T/TProduct Origin:

ChinaColor:

Silver whiteShipping Port:

Xiamen ,ChinaLead Time:

30 days after advance payment

home appliance panel nameplate screen printing machine LTA-4050 , Combined with Feeder , a screen printer , a set of UV dyer was assembled tegother on hot air dryer . This machine is epesically suitable for printing all kinds of home appliance panel nameplate.

Characters :

1. Japan brand servo motors to ensure precision and stability.

2. Japan brand PLC and frequency converter for machine control.

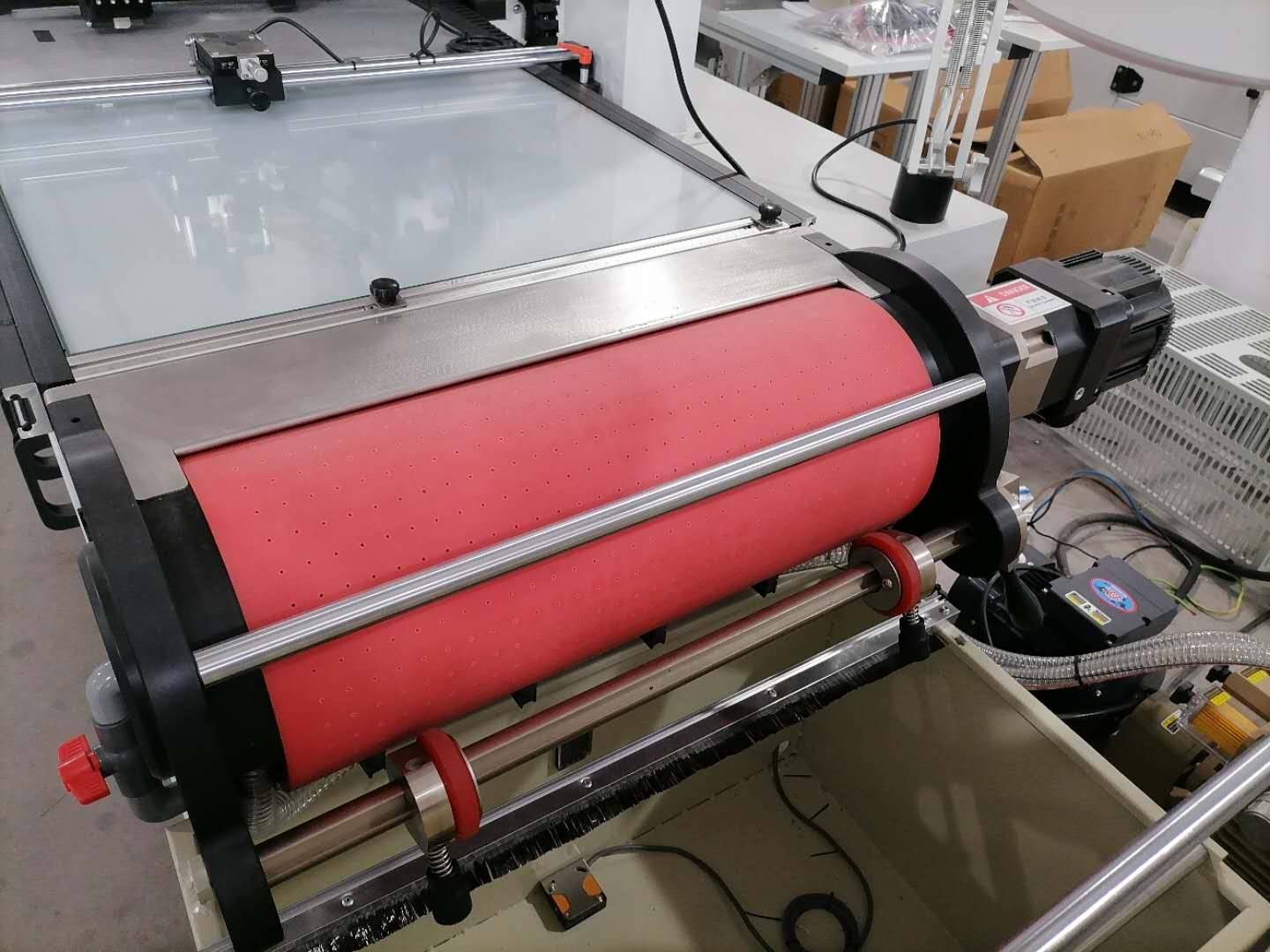

3. Vacuum pulling drum for film feeding.

4. English touch screen control panel.

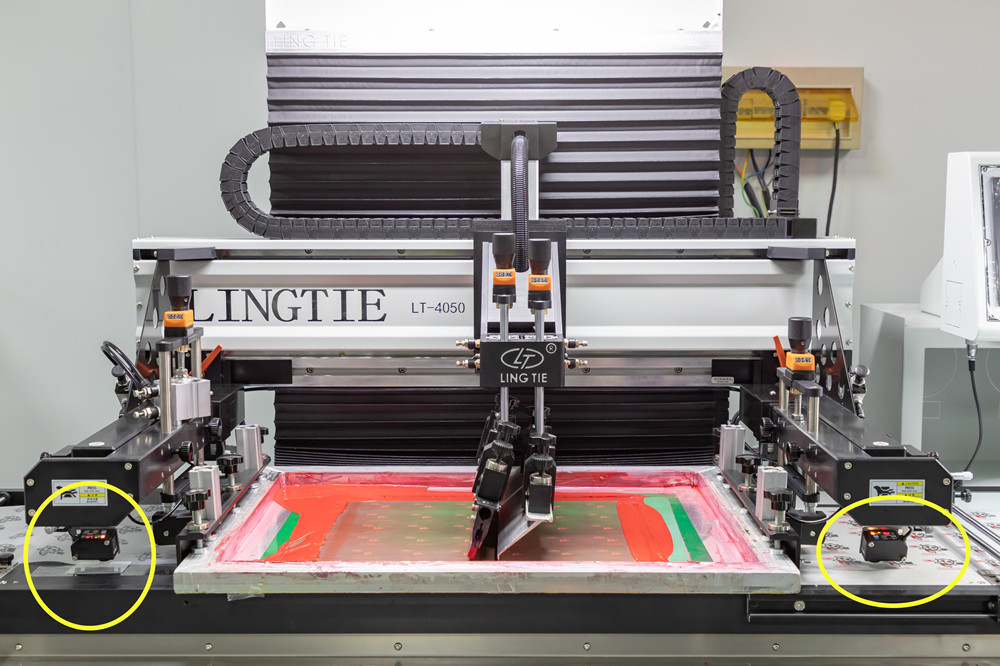

5. Vacuum table, white light lamps under the table for printing quality inspection. 6. Three photocell sensors, one for sensor mark, two on the right & left of screen clamps for web guide.

7. Machine body surface is painted by electrostatic spraying, resistant to rusting.

Parameter:

Printing Area

400*500mm

Printing Speed

0~6000 pcs/hr.

Screen Frame Area

700*900mm

Max. Substrate Width

430mm

Registration Accuracy

±0.01mm

Air Comsumption

0.4-0.6mpa

Power

220V, 3KW, 15A

Frame Adjusting Variable

60mm

Printing Substrate Thickness

0.02~0.5mm

Weight

1500kgs

Dimensions

2620*1100*1700mm (L*W*H)

Taiwan 4-column precision linear slide

Japan Yaskawa Servo Motor

Japanese IKO、EASE or American UBC bear

Taiwan Jscc speed reducer

Taiwan Shihlin electric appliances controller

Taiwan Hiwin precision linear guider

Japan Mitsubishi 10 inch man-machine large screen, Mitsubishi latest PLC

Japan panasonic sensor

Detail picture show :

- Feeding Machine

| Max.Substrate Width | 400mm | |||

| Motor Power | 0.6kw | |||

| Power Supply | 220V/1phase | |||

| Tension | 1-25N | |||

| Weight | 250kgs | |||

| Dimensions | 1030*900*1100mm (L*W*H) | |||

A: 3-inch air shaft for loading raw material. Charge compressed air into the shaft by the air nozzle, the air shaft will inflate and hold firm of the paper core. Press the air nozzle to let the air inside go out of the shaft, the shaft will become smaller, you can take out the paper core.

B: air gun for charging compressed air into the air shaft.

C: the unwinder power switch and indicator, press the power switch to open and close the power of the unwinder.

D: touch screen for unwinder operation.

E: web-guiding system for PVC film deviation correction, so the film will be fed straight to the printing machine.

F: Splice station with 2 clamp bar for press material when change roll or connect or splice material .

2. Screen printing machine

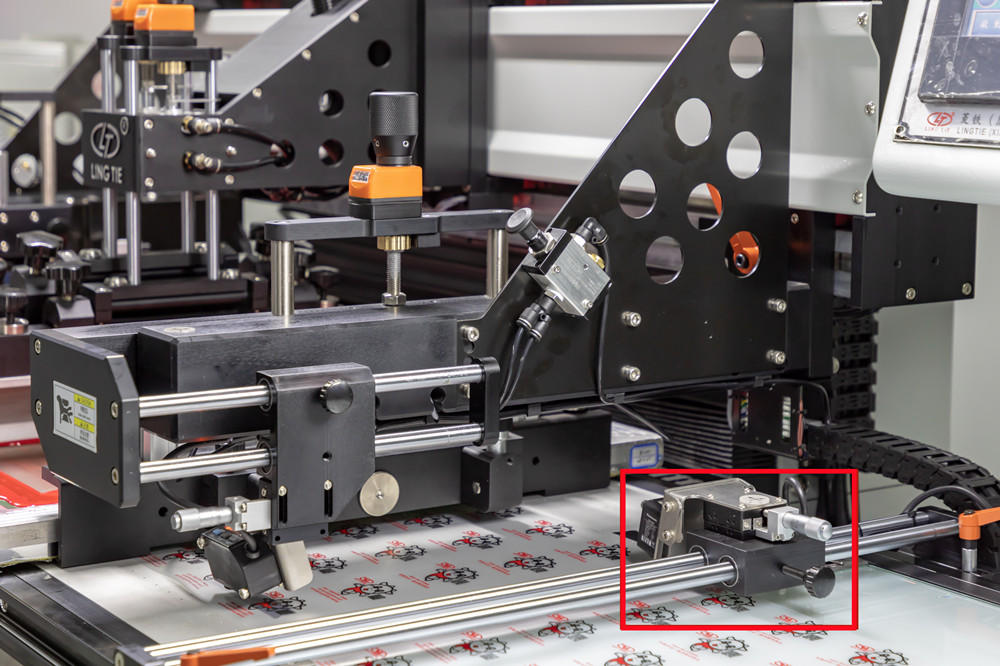

A. There is a small servo motor inside which is the drive of two sensors on the arm for film edge alignment during repeat printing.

B. Pansonic sensor for repeat printing ,to read the sensing mark or hole or color in X direction. This sensor works together with two edge aligment sensor ,ensures high printing precision +-0.01mm

C.The printing table is vacuum table, when the film start feeding and in the feeding process, the vacuum is automatically closed, when the film feeding stop and during printing process, the vacuum is automatically opened to hold the film firm and flat on the table for nice printing on it

D. Nice quality vacuun pulling cylinder.

3.Hot air dryer LTB-600

| Power | 22kw | |||

| Temperature | room temperature ~150℃ | |||

| Heat Insulation Layer Thickness | 100mm | |||

| Tempearture Controller | 4cs | |||

| Fan | 6pcs | |||

| Weight | 900kgs | |||

| Overall Dimensions | 2830*1060*2150mm (L*W*H) | |||

A.Inner loop length 60-meter.

B. 4-side heating and each side temerature can be controlled separately.

C. Deviation correction device for trimly rewinding the printed material.

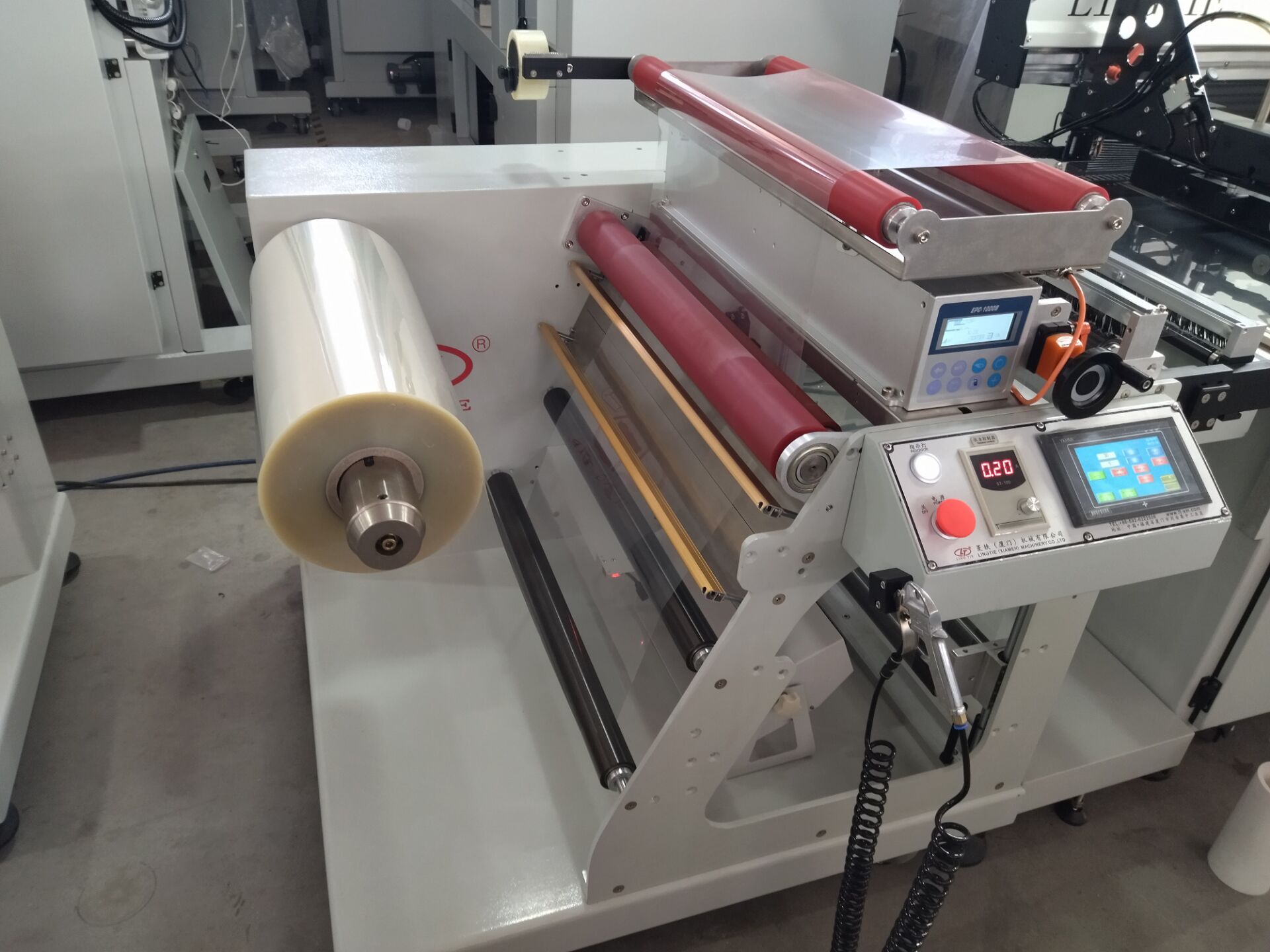

D.lamination function for option.

E.Uniform speed function

F.Substrate conveying speed can be adjusted.

G. Automatic rewinding the substrate after drying process.

H.Wheels in the bottom for easy moving.

I.Japan brand frequency converter.

J.Machine body surface is painted by electrostatic powder spraying, resistant to rusting.

-

Roll to Roll Screen Printing Machine

Roll to Roll Screen Printing Machine

This is specially-designed web-fed screen printing machine for flexible stock, in a roll such as RFID, Electronics-FCB (Flexible Circuits Board), Membrane Switch, IMD and Diffusers, Heat transfer paper/film, rubber vulcanization, Stickers, OPP, PVC, PC, PET, Plastic Leather, Aluminum Foil and so on.

-

PET Film Screen Printing Machine

Find here the PET Film Screen Printing Machine which provides high-quality printed product to help any silk screen printing company the high demands to come true.

-

Heat Transfer Label Screen Printing Machine

Heat Transfer Label Screen Printing Machine

The Cost-optimal Heat Transfer Label Screen Printing Machine comes from the Lingtie (Xiamen ) Machinery manufacturer, it has 15 years of professional printing experience.

-

RFID Screen Printing Machine

RFID Screen Printing Machine

This RFID Printing Machine is used widely on some high precision labels such as RFID Antenna, adapt to the electronics industry. RFID is short for Rodia Frequency Identification.

-

Roll Screen Printing Machine Samples

Roll Screen Printing Machine Samples

All of the Samples come from the customer's factory, and we could send all kinds of samples to you if possible.

-

Automatic Roll to Roll Screen Printing Machine

Automatic Roll to Roll Screen Printing Machine

The web-fed roll to roll screen printing press with powder machine widely applied in Non-woven fabric and garments industry.

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062