After-Sales Service Notice for Turkey Region

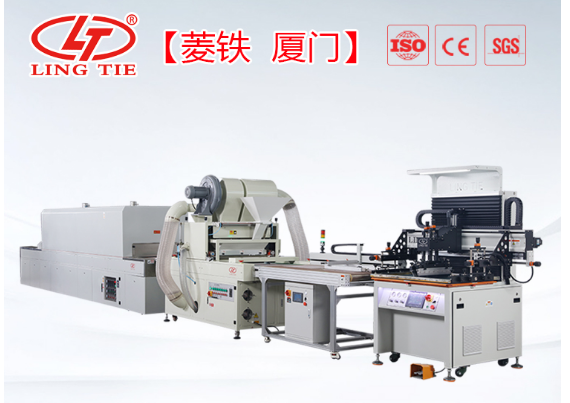

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

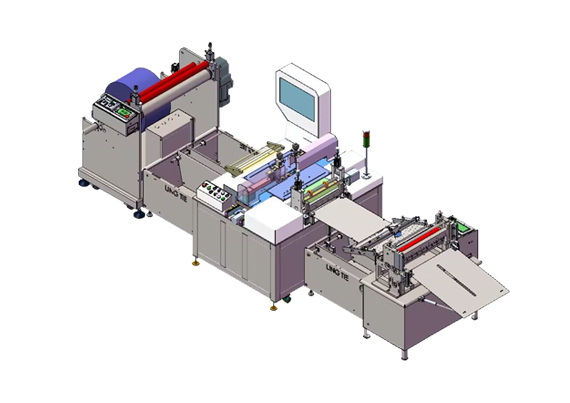

roll to sheet punching cutting machine

Brand:

LingtieItem NO.:

ZLG-500CPrice:

$128000Product Origin:

ChinaColor:

silver whiteShipping Port:

Xiamen portLead Time:

15days

Automatic foil winding and punching machine features:

- Easy operation: Set the working mode directly on the computer monitor.

- High precision: The camera within the recognition range automatically locates the image, and the computer analyzes and controls the movement.

- Fast speed: The camera has a short response time, and once the image is found, it can punch the hole at the position of the image.

- Powerful functionality: Sampled images can be saved and directly accessed through the computer system, allowing real-time software upgrades.

- Quality assurance: Major components such as pressure regulating valves, cylinders, solenoid valves, and linear guides are imported, ensuring their longevity.

- High recognition rate: A special light source can automatically identify positioning hole patterns on highly reflective and highly opaque materials, and can compensate for incomplete image.

The dual-head automatic punching machine system captures sampled graphics within the visible range of the camera through a computer. The analysis involves controlling the displacement of the transmission components and punching with pneumatic components. It meets the customer's requirements for high punching speed, high precision, and ease of operation.

① The punching machine is commonly referred to as a target hole processing device. Target holes were first used in the PCB multi-layer circuit board lamination process. In recent years, positioning punching machines used for positioning processing are commonly called "target shooting machines". Since the machining accuracy of target holes directly affects product precision, punching machines, equipped with CCD vision positioning scanning and computer-controlled automatic positioning systems, can achieve positioning hole machining accuracy and stability within the range of 0.015 millimeters. Therefore, an increasing number of companies have introduced punching machines as dedicated equipment for positioning processing to replace traditional manual drilling. This greatly improves product quality, reduces scrap, saves costs, and increases production. It enhances the market competitiveness of enterprises and is a secret weapon that many companies keep silent about.

② Punching machines can be classified based on the degree of automation into manual punching machines, automatic positioning/alignment punching machines, and fully automatic punching machines. They can also be categorized based on the processing objects, such as flexible board punching machines, membrane switch punching machines, film punching machines, nameplate punching machines, and mobile phone explosion-proof film punching machines. As a professional punching machine manufacturer, our company mainly produces punching machines for flexible circuit boards, circuit boards, PCBs, thin film circuit boards, as well as signs, nameplates, and mobile phone film punching with positioning holes.

Automatic punching machines have specific requirements for graphic recognition in high-precision positioning punching. They require clear and uniformly circular graphic lines for positioning. In the case of incomplete graphics, high opacity, or insufficiently clear printing, the automatic punching can be achieved through software recognition and repair or the selection of appropriate sources.

-

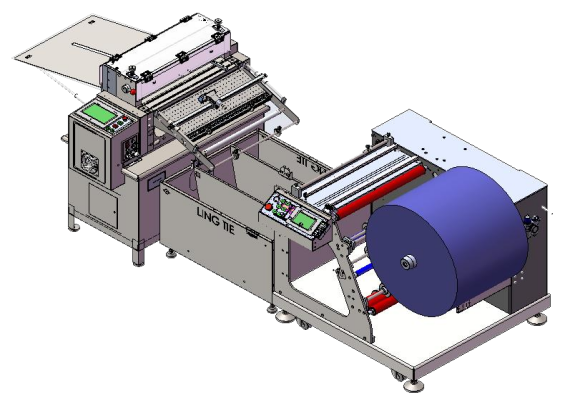

Roll to Sheet Cutting Machine

Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine widely used in Apparel, Beverage, Chemical, Commodity, Machinery, Hardware, Medical.

-

Automatic Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine

This printed paper roll to sheet cutting machine belongs to the post-press printing equipment, match with an ancillary apparatus like rewinding machine using.

-

Roll to Sheet Cutting Machine LTG-600

Roll to Sheet Cutting Machine LTG-600

Roll to Sheet Cutting Machine , the cutter for cutting labels or roll material up to a width of 600 mm.

-

semi-automatic sheet screen printing machine with oven

semi-automatic sheet screen printing machine with oven

Full servo control screen printer with high accuracy ,combined with automatic mechanical arm to save labor cost .

-

Slitting machine with round blade

Slitting machine with round blade

This slitting rewinder is ideal for manufacturers seeking efficiency, precision, and automation in their converting processes

-

Sheet screen printing machine

Sheet screen printing machine

Semi-automatic screen printing machine, with servo motor driving , High-quality and precise lift motor for accurate printing and alignment.

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062