After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

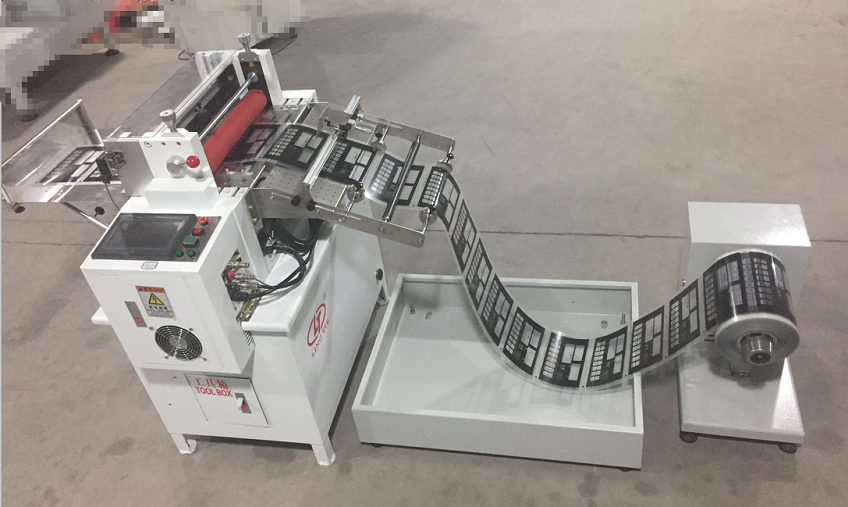

Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine widely used in Apparel, Beverage, Chemical, Commodity, Machinery, Hardware, Medical.

Brand:

LingtieItem NO.:

LTG-500 mmPayment:

T/T, T/C, Paypal, Western Union...Market Price:

$8500Price:

$8500/setProduct Origin:

XiamenShipping Port:

XiamenLead Time:

7 workdays

Product Name: Roll to Sheet Cutting Machine

Export 80 sets to all parts of the word every year, which the roll to sheet cutting machine line composes to cutter machine, case, and feeder machine together.

With unmatched 2-year Spare Parts and labor limited maintenance, all Lingtie Brand Roll to Sheet Cutting Machines designed for worry-free 24/7 running.

Features:

1. The machine is suitable for cutting copper foil, aluminum foil, PET, PC, PVC, PCB, FPC, lithium battery membrane, flannelette, sheet metal, etc. All kinds of coil material cutting.

2. This machine adopt servo motor to pull material, imported PLC touch screen operation, can be set arbitrary length, quantity, speed, can cut single authoritarian.

3. This machine is used with the function of automatic feeding, loading axis adopt gas rose axis, make the operator handling convenient.

Application

The Roll to Sheet Cutting Machine feeding & cutting is done automatically by the machine at one time. The thickness of main baking products ranges from 0.02--15 mm in flat packaging materials; it is widely used in PVC, PET, PP, PC, BOPP, all kinds of film coils, IMD, IMF, IML, various types of electrical appliances. Boards, Membrane Switches, FPC Flexible Circuit Boards, Thermal Transfer Films, Non-woven Fabrics, Color Automotive Labeling, Water Labeling, Ceramic decals, Heat Transfer Paper, Tetoron, Fabrics, Artificial Leather, Leather, etc.

Details Features about the Roll to Sheet Cutting Machine

- Tolerance is 0.05 mm

- Cutting speed is 110 m/ min

- Cutting precision is 0.01 mm

- Max. cutting width is 500 mm

- Max.cutting length is 0.1~9999.9 mm

- Material thickness is 0.5 mm-15 mm

- Warranted time is 12 months

- the Volume of the machine is 1.9 cubic meter

- Powder Supplier 1.2 KW, 220 /380 Voltage

- very Limited maintenance during your using time.

How many parts of this Reel to Sheet Cutting Machine?

-

AC Contactor

- Servo Motor (Made in Japan )

- Air Suction Motor (Made in China )

- Cutting Knife Motor (Made in China )

- PLC & Touch Screen display

- Automatic Electric eye ( ensure cutting precision reach to 0.01 mm )

FAQ

Q:Are you manufacturer or trader?

A:We are manufacturer.

Q:Where is your factory location?

A:Our factory is located in Xiamen city of China, just opposite to Taiwan.

Q:How can I visit your factory?

A:Xiamen city have an international airport and high speed train station. Transportation to Xiamen from foreign countries or from other China cities is very convenient by train or by air.

Q:Can you arrange a pickup from airport or train station if l visit your factory?

A:Yes, we can go to airport or train station to pick you up.

Q:Can you design or modify the machine according to my requirement?

A:Yes, we can design or modify the machine according to your requirement.

Q:Where certificate do you have?

A:We have CE, SGS,ISO90001 and patent certificate.

Q:What is your payment term?

A:30% advance by T/T, 70% balance paid before shipment or L/C at sight.

Q:What is the delivery time after advance payment.

A:Usually we can deliver ordered machine 15-30 days after receiving advance payment.

Q:What is the warranty for your machine.

A:Our machine warranty is 12 months after installation. We also offer lifetime maintenance for our machine.

Q:Do you offer installation and training service for your machine?

A:Yes, we can go to your factory for machine installation and operator training.

-

Automatic Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine

This printed paper roll to sheet cutting machine belongs to the post-press printing equipment, match with an ancillary apparatus like rewinding machine using.

-

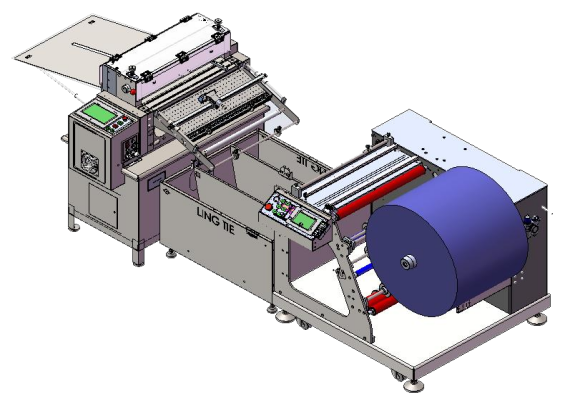

Roll to Sheet Cutting Machine LTG-600

Roll to Sheet Cutting Machine LTG-600

Roll to Sheet Cutting Machine , the cutter for cutting labels or roll material up to a width of 600 mm.

-

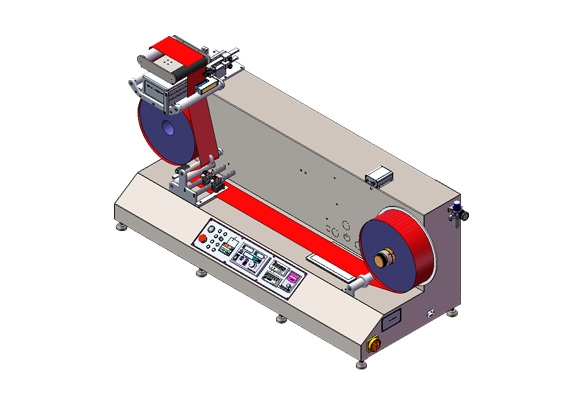

roll to sheet punching cutting machine

roll to sheet punching cutting machine

Roll to sheet punching and cutting machine , combined with a unwinder ,a punching module, a sheeter .

-

Flatbed silkscreen printing machine

Flatbed silkscreen printing machine

Flatbed Screen Printing Machine, which consists of a feeder unit + screen printing station + IR dryer , you can choose a feeder unit + multi-color screen printing stations + die cutting machine.

-

Automatic Rewinding Machine with Slitting

Automatic Rewinding Machine with Slitting

Automatic rewinder with slitting label function. Round knife can cut products quickly and accurately. The protective cover with the same name is safe and beautiful.

-

Customized label counter for laser printer installation

Customized label counter for laser printer installation

Customized label counter ,with constant rewinding speed .which with 1metre space between unwind and rewind shaft . enough space for installing inkjet printer , laser printer ,TTO printer . etc

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062