After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

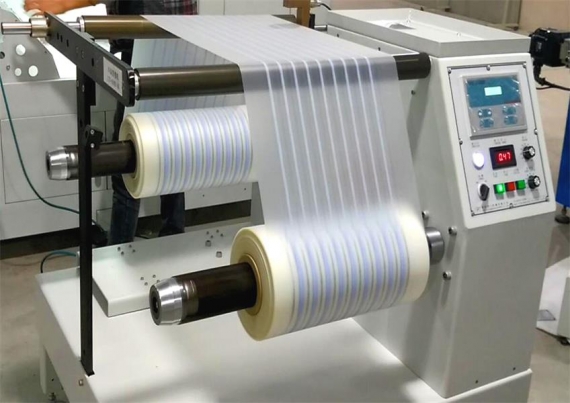

Heavy duty jumbo roll rewinding machine with deviation correction device

Brand:

LingtieItem NO.:

LTD-600 EMarket Price:

$7000Color:

silver whiteShipping Port:

Xiamen,ChinaLead Time:

7days

- Deviation correction device to make sure straight rewinding;

- Meter counter ;

- Automatic tension control;

- Pneumatic clamp device support material rewinding well.

Main Model and Parameter:

| Model | LTD-600 E |

LTD-1000 E |

|

| Max.Web width | mm | 600 | 1000 |

|

Max.Loading weight |

kg | 300 | 300 |

| Max.diameter | mm | 900 | 900 |

|

Power supply |

V/kw | 220/1.7 | 220/1.7 |

| Tension | N | 100 | 100 |

|

Net.weight of Machine |

kg |

698 | 786 |

| Machine dimension | mm | L2110*W1450*H1250 |

L2110*W1860*H1250 |

|

Electric controller weight |

kg |

90 | 90 |

|

Electric controller dimension |

mm |

L600*W500*H900 |

L600*W500*H900 |

Features of automatic double arm rectification rewinder:

1. Adopt imported brand JSCC motor, reducer and stepless speed change to ensure stable operation of the machine.2. Using DC deviation correction control system, the machine runs smoothly, silently and durable.

3. Using ultrasonic sensor, it can sense transparent materials.

4. Imported bearings are used to ensure that the machine runs all day long.

5. Using electromagnetic brake, tension control is convenient, flexible, and data management is possible.

6. Using Japanese MITSUBISHI inverter, precise speed control, stable start and stop, precise and durable.

7. Speed control digital display, can be adjusted at will, convenient adjustment operation and data management.

8. Long service life, low failure rate, universal spare parts, sufficient inventory and strong interchangeability.

9. Special design, automatic loading and unloading, suitable for large diameter and heavy materials.

10. Optional PLC uniform speed function, large and small coil diameters, to ensure consistent linear speed.

11. Using semi-automatic tension control, the tension can be adjusted automatically following the size of the roll diameter or manually.

12. The retracting and discharging shafts are all air-inflated shafts, which only need to be easily inflated, which is suitable for all kinds of people to operate.

13. The machine will automatically stop and alarm when the deviation is corrected to the limit. When the machine is unattended, it will automatically stop and alarm after the machine is finished running.

14. The fuselage adopts powder electrostatic spraying, which is environmentally friendly, solvent-resistant, durable and does not fall off the paint.

-

Winding Rewinding Machine

Winding Rewinding Machine

A Winding rewinding machine is a machine designed for making the unwinding edge straight, slitting the big roll to small rolls. This machine also used for ink jet printing.

-

Automatic Rewinding Machine

Automatic Rewinding Machine

A rewinding machine is a machine designed for making the unwinding edge straight, slitting the big roll to small rolls.

-

Doctoring Rewinding Machine

Doctoring Rewinding Machine

An Automatic rewinding machine is a machine designed for making the unwinding edge straight, remove dust on the film surface. This machine also used for ink jet printing.

-

Roll Rewinding Machine

Roll Rewinding Machine

This customized Doctoring Rewinding Machine used for the medical gauze rewinding under the consistent tension by a Japanese professional enterprise.

-

Rewinding laminating machine

Rewinding laminating machine

Automatic Rewinding machine with laminating and protect film peel off function .

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062