After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

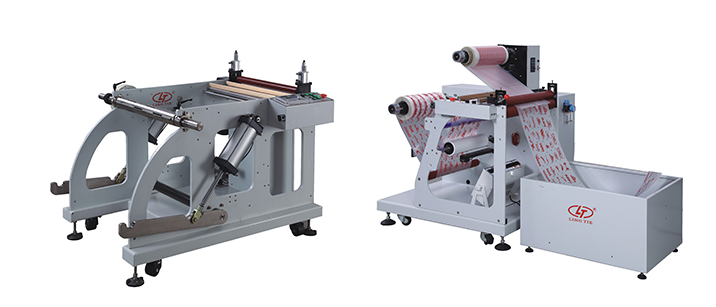

Roll to Sheet Cutting Machine LTG-600

Brand:

LingtieItem NO.:

LTG-600Payment:

FOB XiamenProduct Origin:

ChinaShipping Port:

XiamenLead Time:

15days

A roll-to-sheet cutting machine is designed to convert rolls materail into sheets with the needed size. The roll is unwound and the web is passed through the guillotine cutter, finally, the finished sheets with the desired length are collected on the plate . This roll to sheet cutting machine can handle max.width 600mm roll material .

This roll ro sheet cutting machien combined with 2 parts ,automatic cutter and automatic feeder

Machine Parameters :

*Automatic cutter :

1 phase /220V

Model

LTG-600

Cutting Length

0.1-9999.9 mm

Allowable web width

0-600 mm

Power

1.7 kw

Voltage

Weight

280 kg

Machine size

L1400* W 1130 *H1100

1. This machine is suitable for cutting copper foil, aluminum foil, PET, PC, PVC, PCB, FPC, lithium battery film, flannel, metal foil and other roll materials.

2. This machine adopts servo motor to pull the material, imported PLC touch screen operation, can arbitrarily set the length, quantity, speed, and can be individually cut.

*Automatic feeder :

Model

LTC-600 E

Max. web width

620 mm

Power

0.5 kw

Powder supply

1 phase /220 V

Weight

380 kg

Machine size

L*1500 *W 1220 *H 1120 mm

1. Using Japanese MITSUBISHI inverter, precise speed control, stable start and stop, precise and durable.

2. Adopt imported brand JSCC motor, reducer and stepless speed change to ensure stable operation of the machine.

3. The feeder is controlled by imported photoelectric switch to avoid scratches. The feeding length can be adjusted automatically.

4. The electromagnetic tension adopts digital display, which can be adjusted at will, which is convenient for adjustment operation and data management.

5. Machine automatically stop when without material.

6. There is a loading and receiving platform, which is convenient for personnel to operate.

7. The unwind shaft is air expansion shaft, which only needs to be easily inflated, which is suitable for all kinds of people to operate.

8. The machine body is powder electrostatic spraying, which is environmentally friendly, solvent-resistant, durable and does not fall off the paint.

9. The machine is equipped with moving rollers, which is convenient for handling

There are different feeding machine for option :

-

Roll to Sheet Cutting Machine

Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine widely used in Apparel, Beverage, Chemical, Commodity, Machinery, Hardware, Medical.

-

Automatic Roll to Sheet Cutting Machine

Automatic Roll to Sheet Cutting Machine

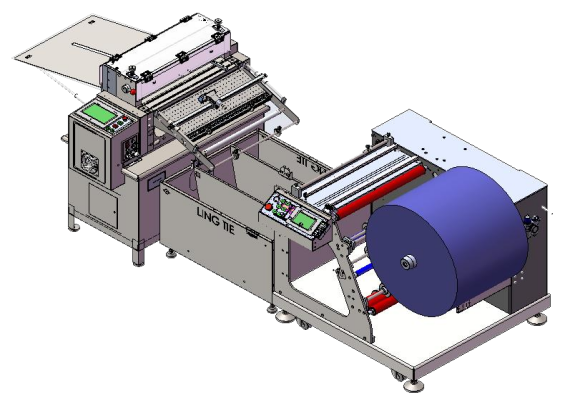

This printed paper roll to sheet cutting machine belongs to the post-press printing equipment, match with an ancillary apparatus like rewinding machine using.

-

roll to sheet punching cutting machine

roll to sheet punching cutting machine

Roll to sheet punching and cutting machine , combined with a unwinder ,a punching module, a sheeter .

-

rewinder with thermal transfer overlay

rewinder with thermal transfer overlay

Rewinding with thermal transfer printing function, It can print date, code, serial number, etc. on label or material in roll form

-

Label Rewinder Machine

Label Rewinder Machine

This Label Rewinder Machine especially--designed used to rewind labels and count the labels numbers for different material labels

-

RFID Screen Printing Machine

RFID Screen Printing Machine

This RFID Printing Machine is used widely on some high precision labels such as RFID Antenna, adapt to the electronics industry. RFID is short for Rodia Frequency Identification.

Call Us : +86-18965820062

Call Us : +86-18965820062 Email : fany@lt-xm.com

Email : fany@lt-xm.com

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062